Compare: Vacuum Circuit Breaker vs Air Circuit Breaker

Introduction

In modern electrical systems, circuit breakers play a crucial role in ensuring safety and reliability. Among the various types available, the Vacuum circuit breaker and the Air Circuit Breaker are two of the most commonly used. Both are designed to interrupt fault currents and protect electrical circuits, but they operate using different arc quenching media. Understanding the differences between these two is essential for engineers, technicians, and industries that depend on safe power distribution. This article by Aierway explores the detailed comparison between a Vacuum Circuit Breaker and an Air Circuit Breaker, highlighting their features, advantages, disadvantages, and applications.

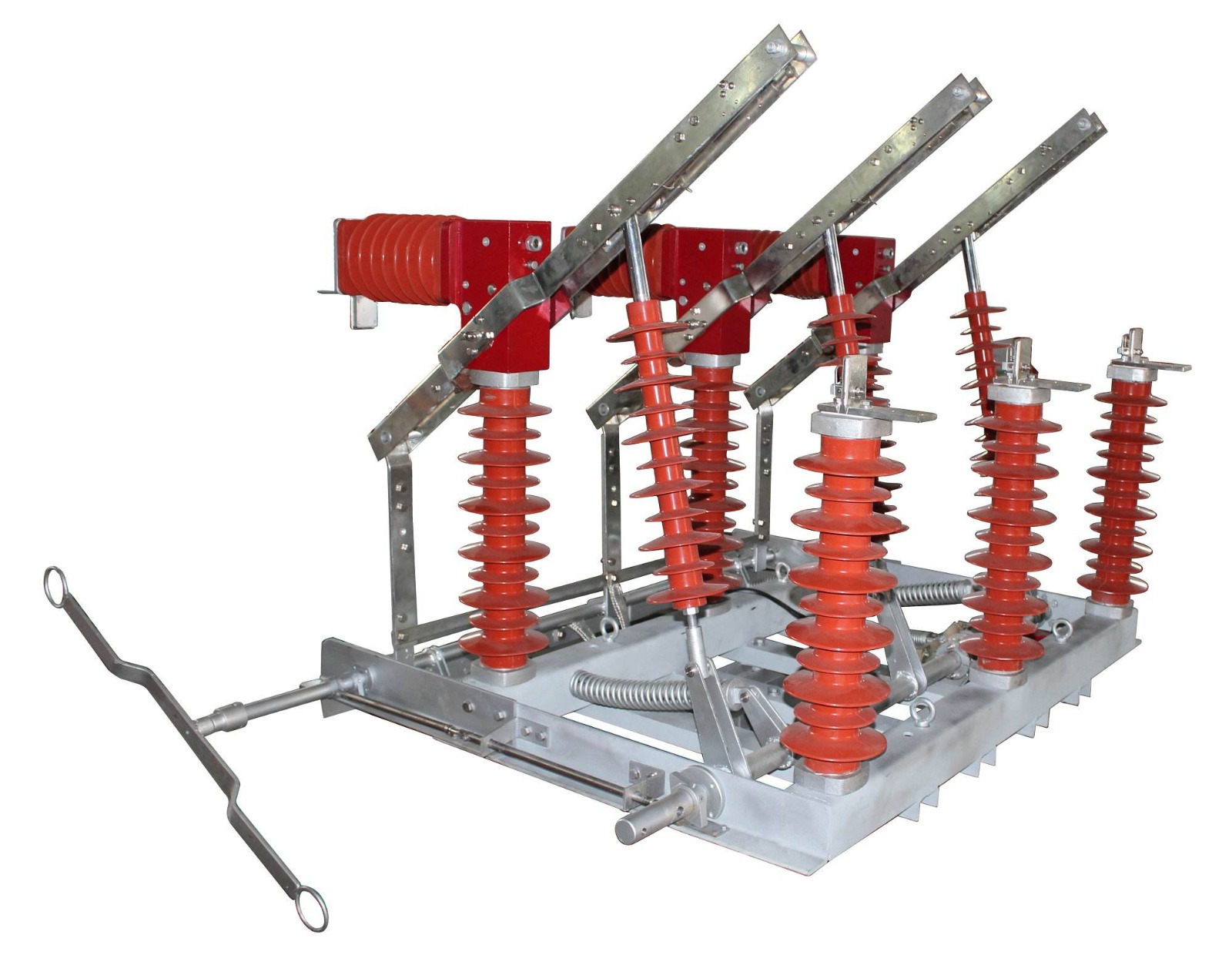

What Is a Vacuum Circuit Breaker?

A Vacuum Circuit Breaker (VCB) is a type of circuit breaker where the arc is extinguished in a vacuum chamber. When the breaker contacts open, the resulting arc is quickly quenched because there are no ionized particles in the vacuum. This makes the Vacuum Circuit Breaker highly efficient for medium-voltage applications, typically ranging from 1 kV to 33 kV.

The Vacuum Circuit Breaker is widely known for its compact size, long service life, and low maintenance requirements. The vacuum interrupter is a sealed unit that prevents contamination and ensures consistent performance over time.

Construction of a Vacuum Circuit Breaker

The Vacuum Circuit Breaker is made up of several key components:

- Vacuum Interrupter – The main part where arc interruption takes place in a vacuum medium.

- Operating Mechanism – Helps in opening and closing the breaker contacts.

- Contacts – Conductive parts that carry the current and separate during a fault.

- Arc Shield – Protects the internal surfaces from metal vapor deposition.

Each of these components works together to make the Vacuum Circuit Breaker efficient and durable under high-stress conditions.

Working Principle of a Vacuum Circuit Breaker

When a fault occurs, the contacts of the Vacuum Circuit Breaker separate, and an arc forms between them. The vacuum medium prevents the arc from sustaining because there are no gas molecules to ionize. The arc is quickly extinguished when the current passes through zero. This process ensures rapid fault clearance and minimizes damage to connected equipment.

Advantages of a Vacuum Circuit Breaker

- High Reliability – The Vacuum Circuit Breaker provides dependable performance due to its sealed design.

- Low Maintenance – It requires minimal servicing because there is no oxidation or gas leakage.

- Long Life – The contacts of a Vacuum Circuit Breaker have excellent endurance against erosion.

- Environmentally Friendly – No harmful gases are emitted during operation.

- Compact Design – The Vacuum Circuit Breaker is smaller and lighter compared to gas or air types.

Disadvantages of a Vacuum Circuit Breaker

While the Vacuum Circuit Breaker is efficient, it also has some limitations:

- It is generally not suitable for very high-voltage applications above 33 kV.

- The initial cost of the Vacuum Circuit Breaker can be higher than that of traditional air circuit breakers.

- The vacuum interrupter is a sealed unit and cannot be repaired; it must be replaced after its service life.

What Is an Air Circuit Breaker?

An Air Circuit Breaker (ACB) uses air as the arc extinguishing medium. When the contacts separate, the arc is cooled and blown out by air movement. The ACB is generally used for low-voltage applications up to 1 kV and is common in industrial and commercial installations.

The Vacuum Circuit Breaker and the Air Circuit Breaker differ mainly in their arc quenching method, size, and maintenance requirements.

Comparison Between Vacuum Circuit Breaker and Air Circuit Breaker

1. Arc Quenching Medium

- Vacuum Circuit Breaker: Uses vacuum as the medium to extinguish the arc.

- Air Circuit Breaker: Uses air for arc extinction.

2. Voltage Range

- Vacuum Circuit Breaker: Suitable for 1–33 kV medium voltage systems.

- Air Circuit Breaker: Typically used for low-voltage systems below 1 kV.

3. Maintenance Requirements

- Vacuum Circuit Breaker: Requires very little maintenance.

- Air Circuit Breaker: Needs regular inspection and cleaning due to dust and oxidation.

4. Size and Weight

- Vacuum Circuit Breaker: Compact and lightweight.

- Air Circuit Breaker: Bulkier due to arc chutes and air channels.

5. Arc Duration

- Vacuum Circuit Breaker: Arc is extinguished within one or two current zero crossings.

- Air Circuit Breaker: Arc duration is relatively longer.

6. Environmental Impact

- Vacuum Circuit Breaker: Eco-friendly, no emission of gases.

- Air Circuit Breaker: Uses air, but may release ionized gases during operation.

Applications of Vacuum Circuit Breaker

The Vacuum Circuit Breaker is widely used in:

- Medium-voltage switchgear systems.

- Industrial power distribution.

- Transformer and generator protection.

- Mining and railway electrical networks.

- Renewable energy systems.

These applications benefit from the Vacuum Circuit Breaker due to its durability, safety, and operational efficiency.

Why Choose a Vacuum Circuit Breaker Over an Air Circuit Breaker?

Choosing a Vacuum Circuit Breaker offers several benefits over an air circuit breaker. It ensures faster arc extinction, longer equipment life, and minimal downtime. The Vacuum Circuit Breaker also has superior performance under harsh environmental conditions and is more energy-efficient. Its sealed vacuum interrupter prevents contact contamination, resulting in stable performance for years.

Future of Vacuum Circuit Breaker Technology

The Vacuum Circuit Breaker continues to evolve with advancements in materials, design, and automation. Smart monitoring systems and predictive maintenance features are being integrated to enhance reliability. The future of power distribution relies heavily on Vacuum Circuit Breaker technology due to its safety, efficiency, and eco-friendly nature.

Conclusion

The comparison between the Vacuum Circuit Breaker and the Air Circuit Breaker clearly shows that the Vacuum Circuit Breaker is the superior choice for medium-voltage applications. It offers enhanced safety, lower maintenance, and longer operational life. While the Air Circuit Breaker still holds importance for low-voltage systems, the Vacuum Circuit Breaker is the preferred solution for modern electrical infrastructures.

By understanding the features and benefits of the Vacuum Circuit Breaker, industries can make informed decisions that ensure power reliability, safety, and efficiency. Aierway proudly emphasizes that the Vacuum Circuit Breaker remains the cornerstone of future-ready electrical protection systems.

Post Comment